Fortunately, most types of failures on Rotating machines can be predicted by measuring, observing and comparing the pattern of vibrations experienced on the machines on continuous basis. The signature analysis of the typical distorted vibrations as against regular pattern convey the type of emerging fault scenario. (bearing failure, shaft misalignment, loose mounting etc) This helps in Predictive maintenance which is more efficient and cost effective in comparison to the typical periodic maintenance.

- Historical baseline vibration values

- Start-up / Shut-down or load-change values

- Pocket-Passing Frequency, (PPF)

- Overloads, Misalignment's

- Low lubrication, Worn out bearings

- Axial & Radial vibrations of shaft

- Mechanical mounting and coupling problems

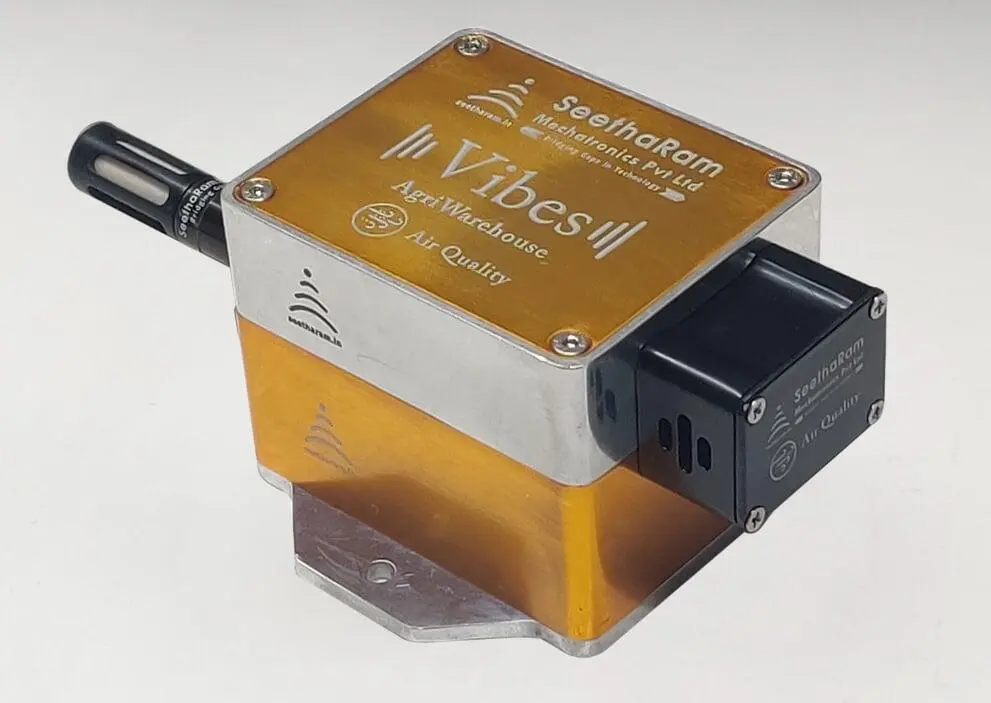

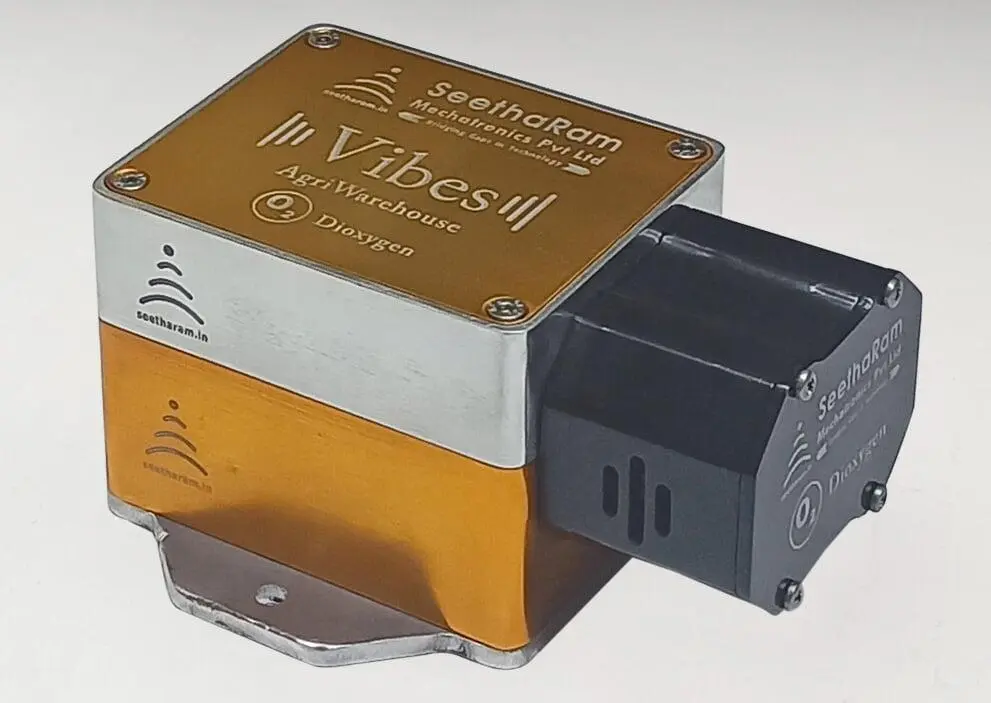

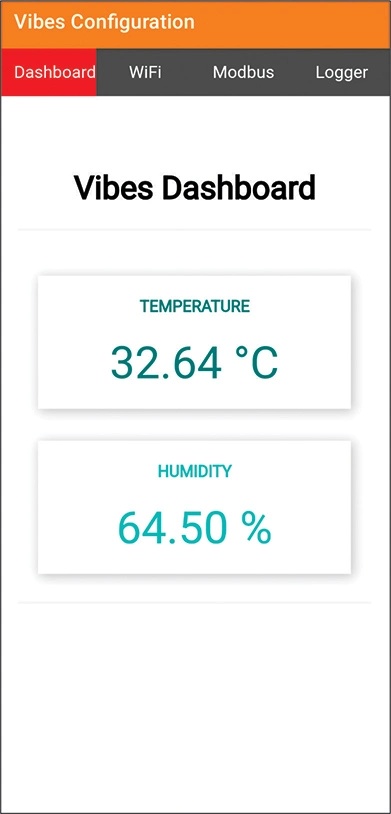

Vibes Configurator - Mobile Applications

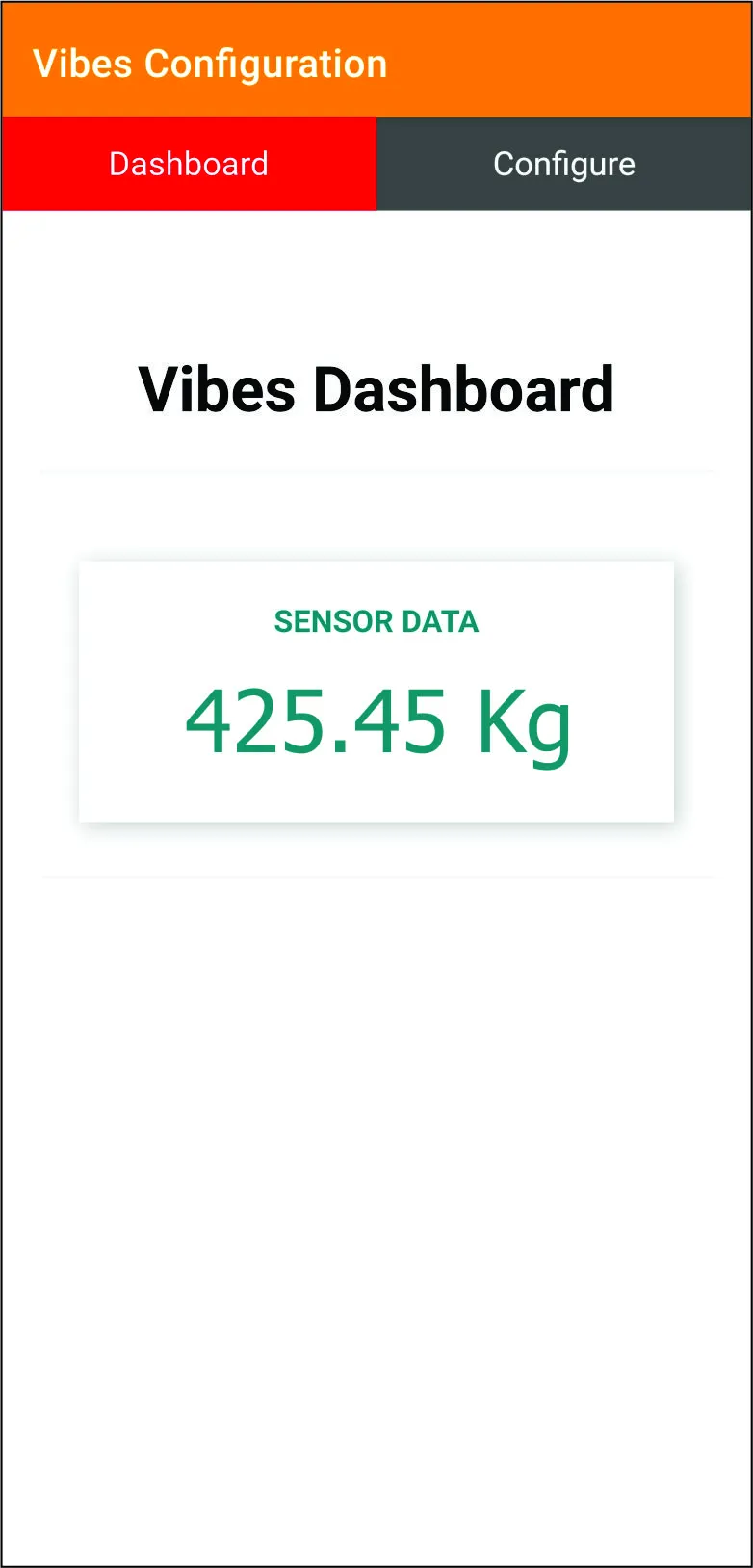

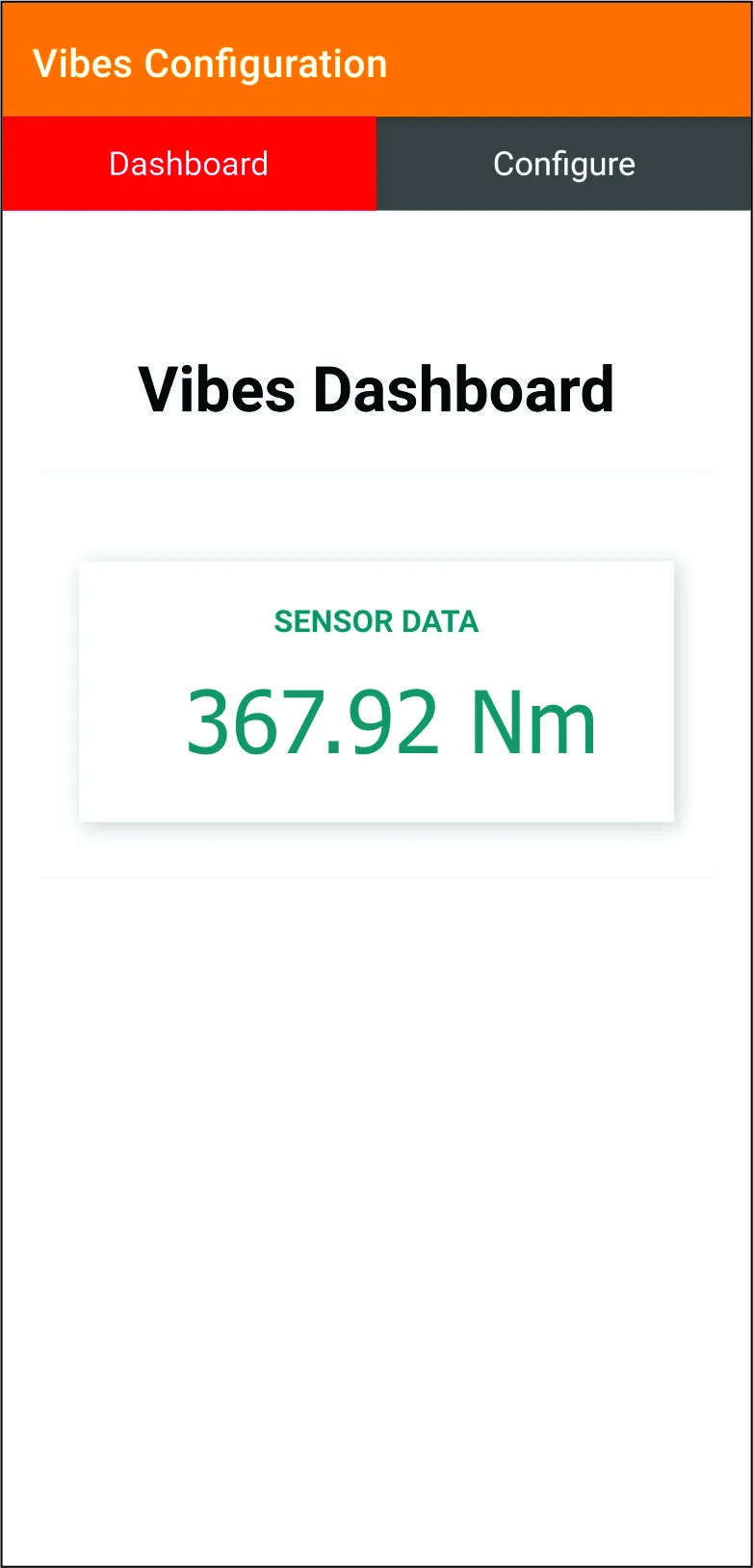

Dash Board

Here you can monitor device data on local dashboard

Vibes Humidity & Temperature Screens

Vibes Load cell Screens

Vibes Torque Screens

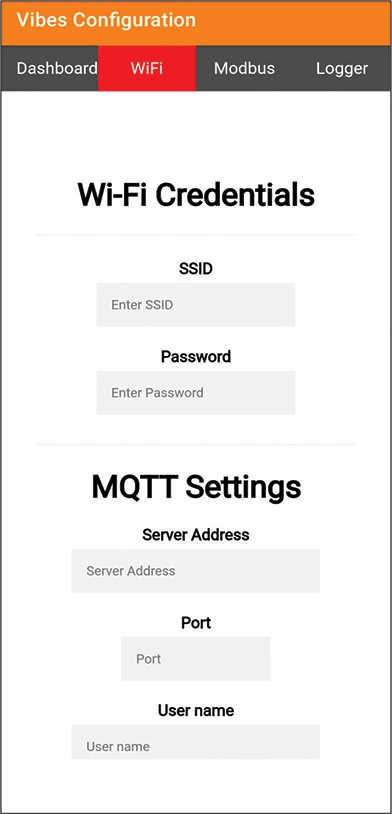

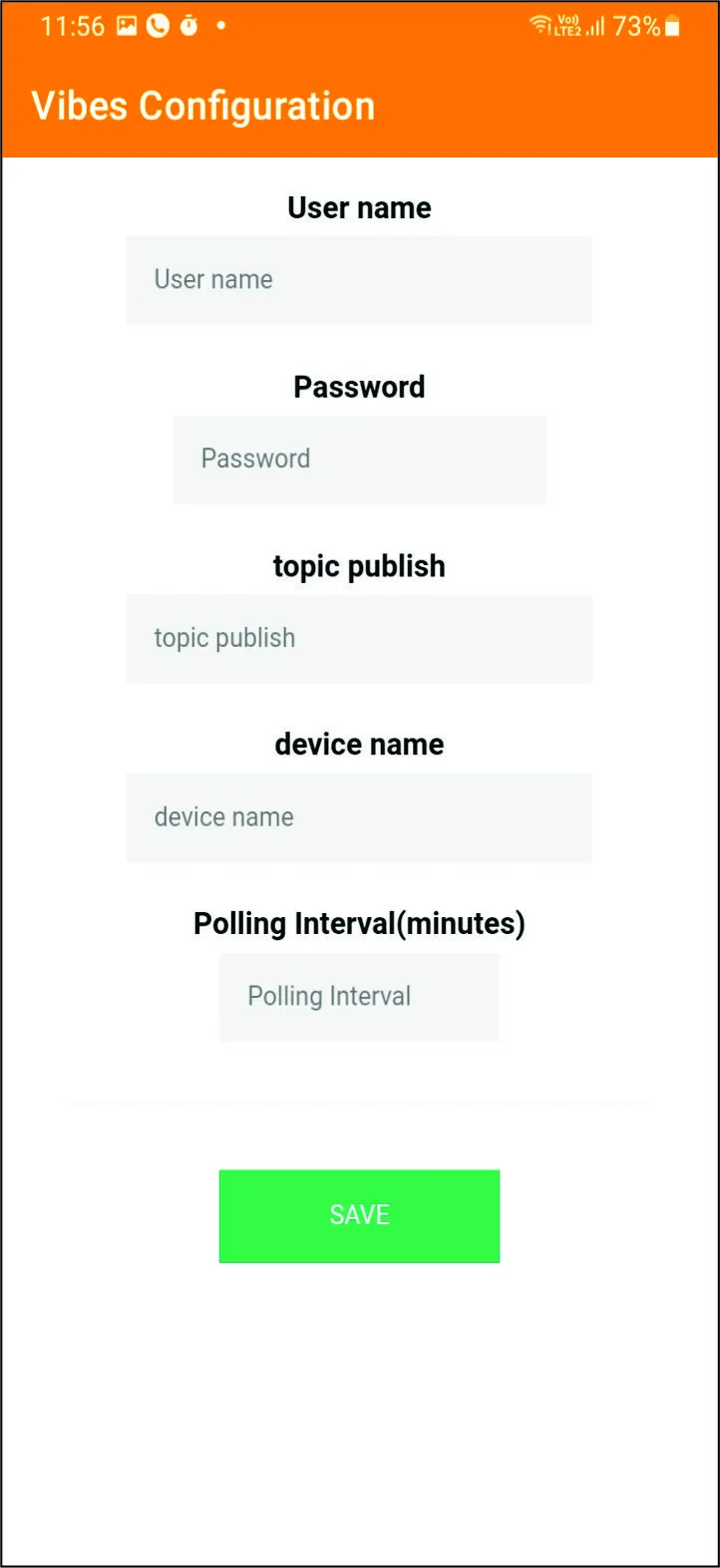

Wi-Fi & Server Configuration

Configure your Wi-Fi SSID credentials & Server credentials to view sensor data on cloud server.

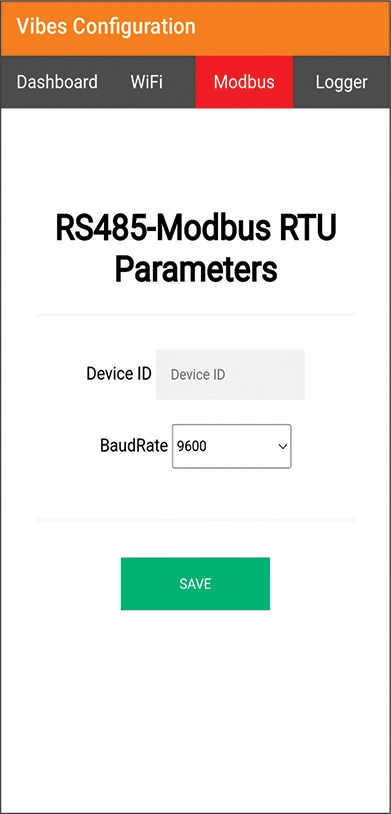

Configuration for Modbus Devices

Configuration for Modbus Devices

Can config the MODBUS Device Id and Baud Rate of the device

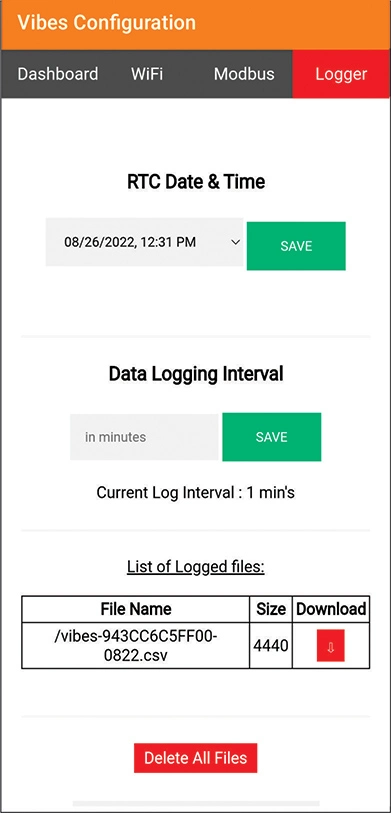

Data Logger Configuration

Can log past data and download the data in CSV format