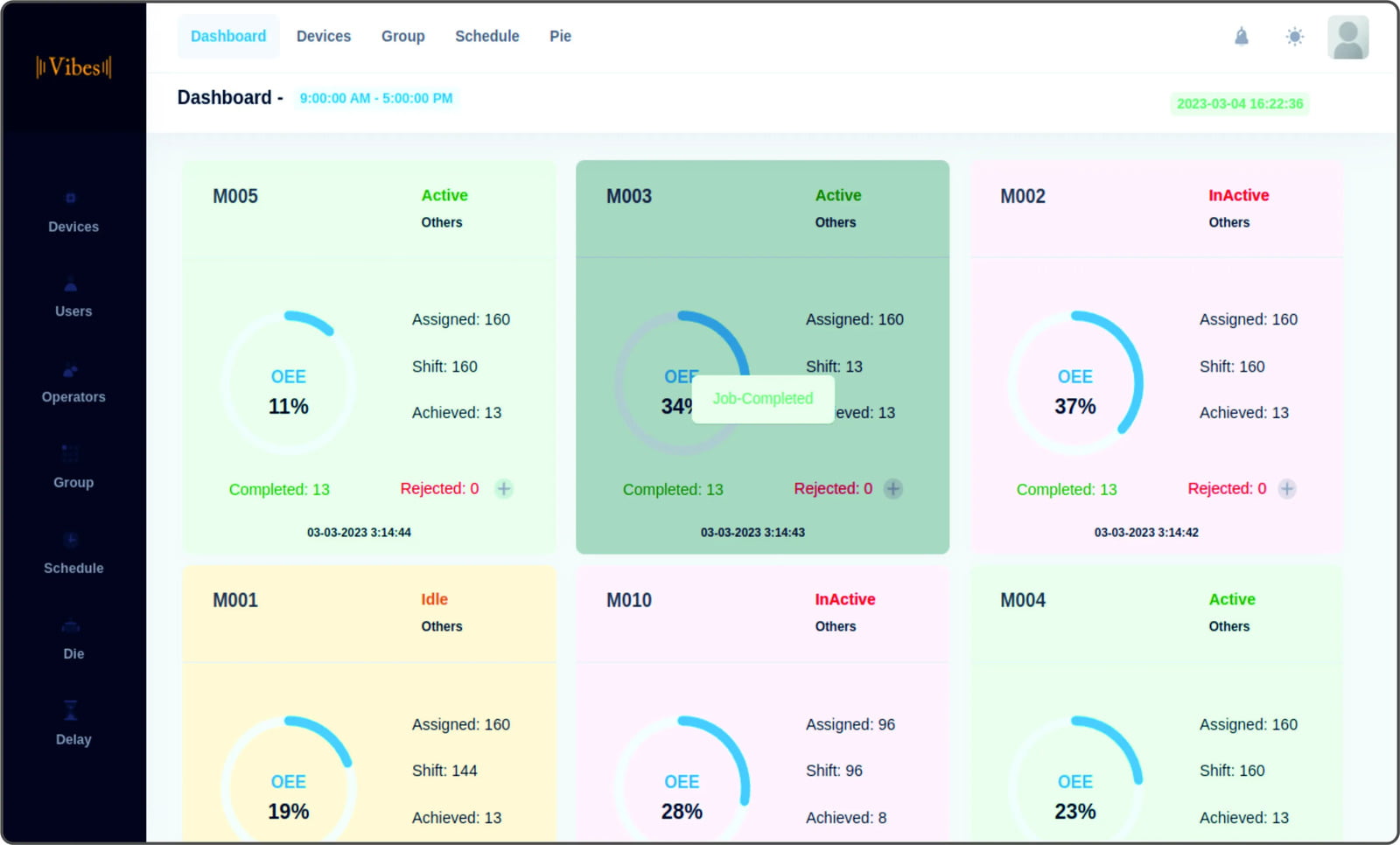

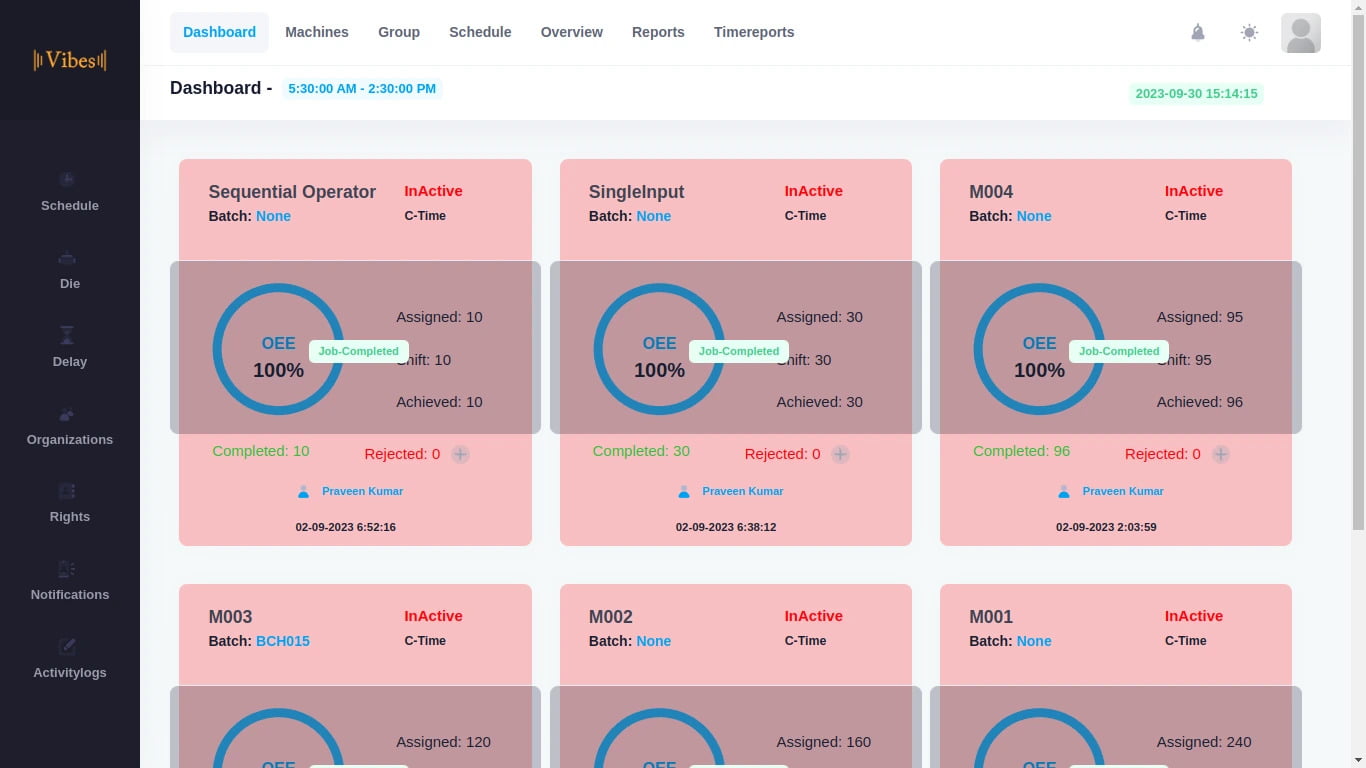

Vibes - OEE (Overall Equipment Effectiveness)

VIBES OEE enhances the manufacturing process by gathering accurate, actionable production data and making it available to stakeholders in real-time. That way, they can make improvements during the shift as opposed to supervisors looking at data retroactively.

Vibes OEE Offers

Rich Data Foundation

Vibes OEE, we can track the losses of each component of our production line and machines. This gives us a detailed picture of the effectiveness of our machines to produce products with extraordinary precision. We can also measure the true potential of our factories by determining how well our manufacturing processes perform.

Because OEE allows us to identify real problems in a more strategic way, eg. Eg staffing, the supply of materials, planning, and changes; it gives us the ability to address these issues directly.

Accurate and Unblased Data in Real Time

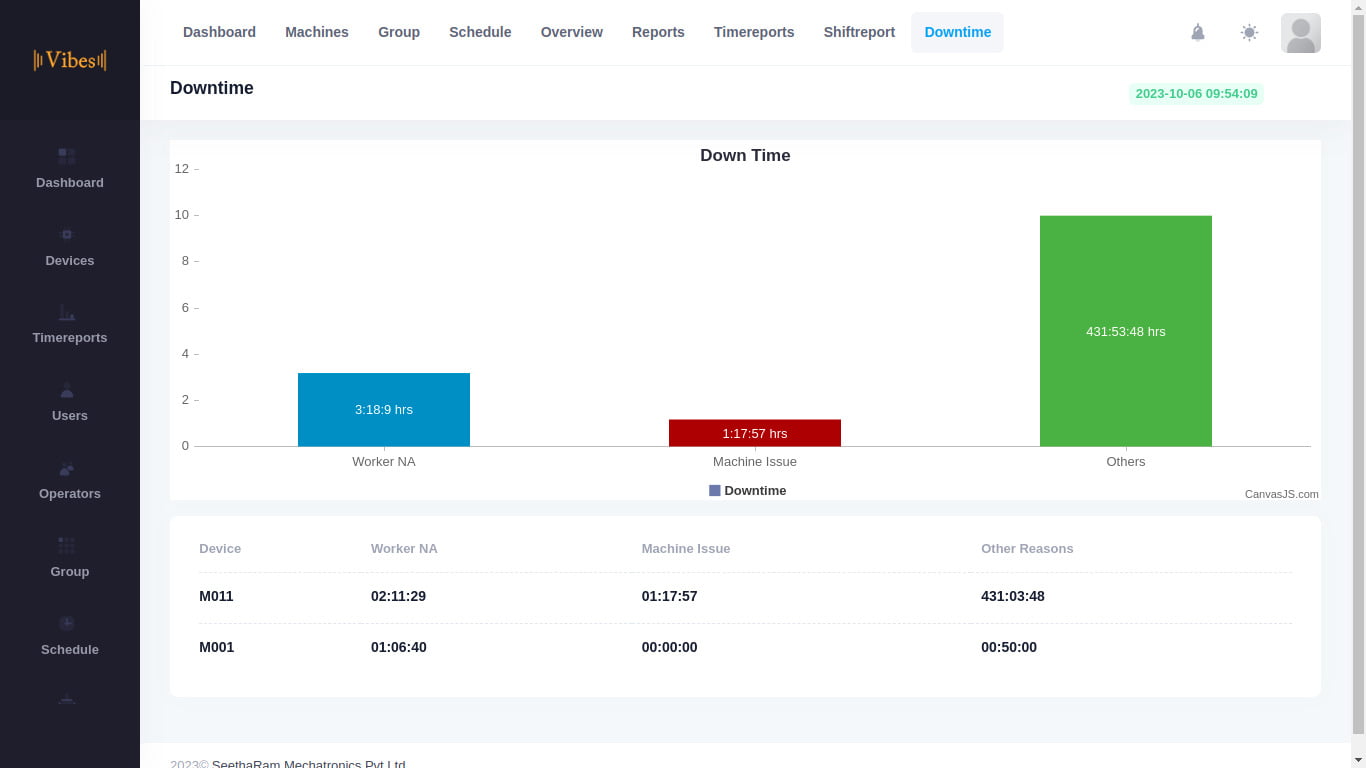

Impact on Machine Availability

1. Planned stops

2. Unplanned stops

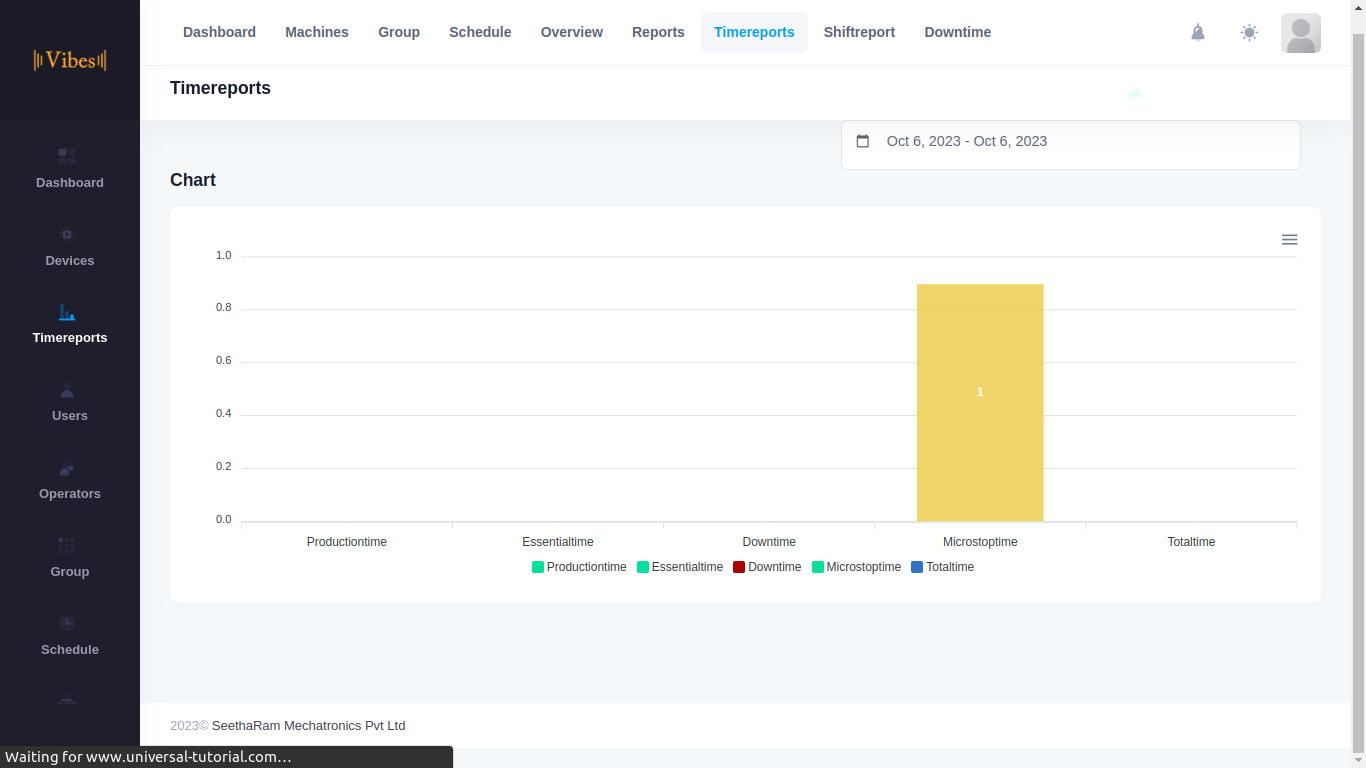

Impact on Machine Performance

1. Micro stops

2. Slow Cycles

Impacting the Quality delivered by the machine:

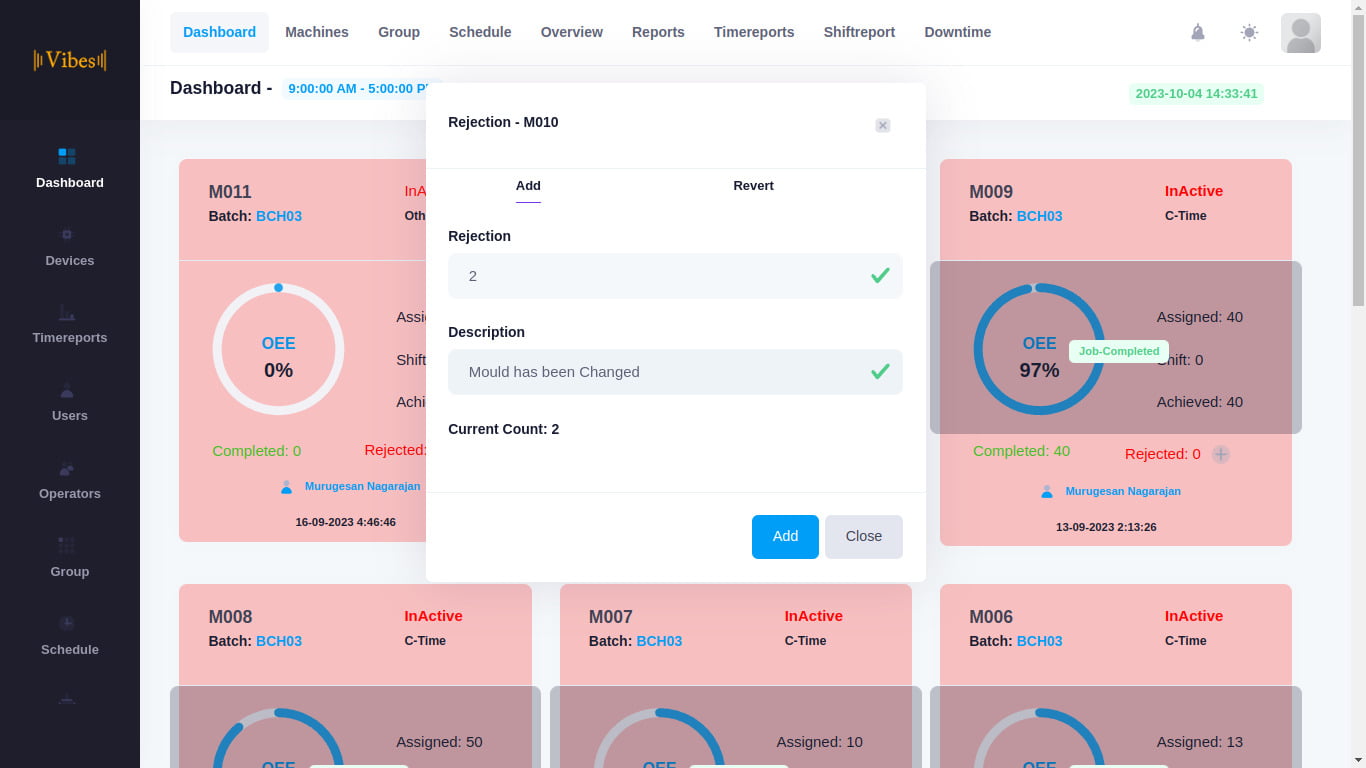

1. Start - Up rejections

2. Production rejects

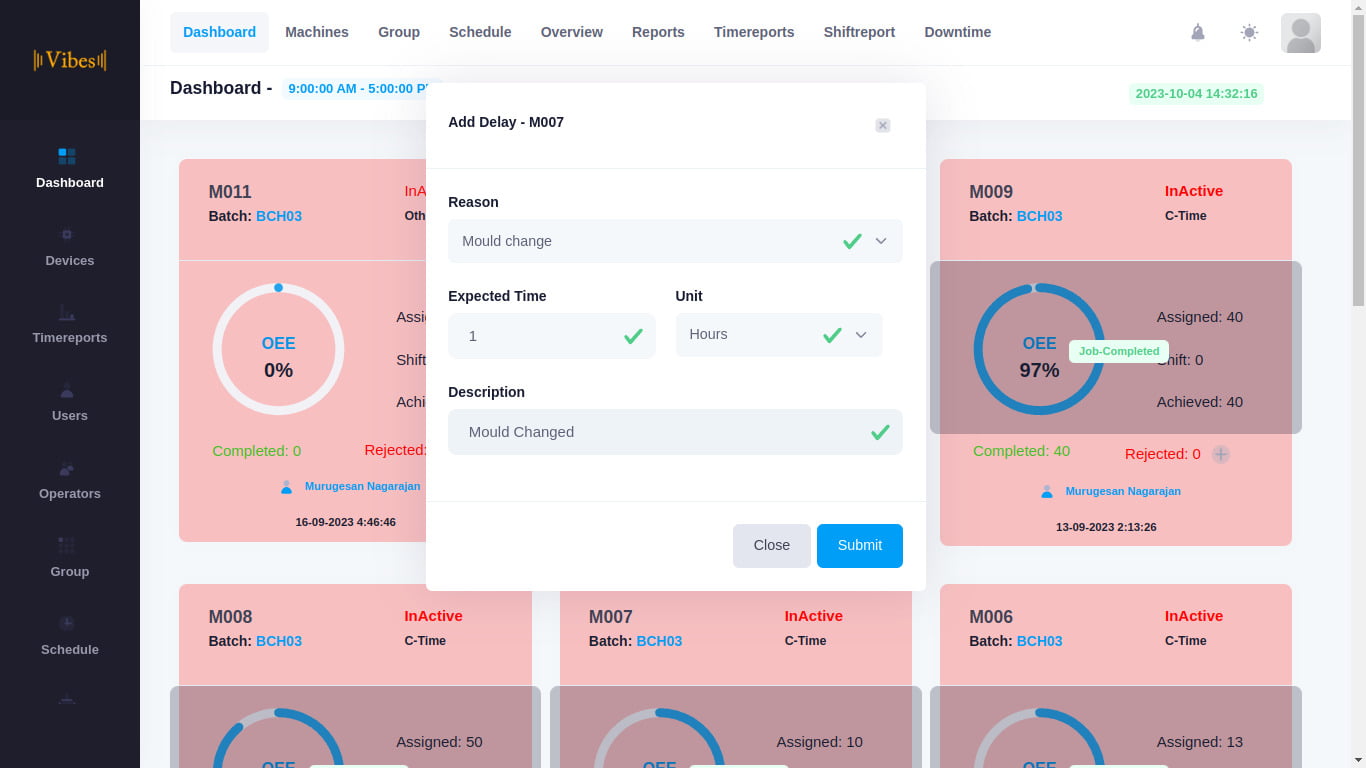

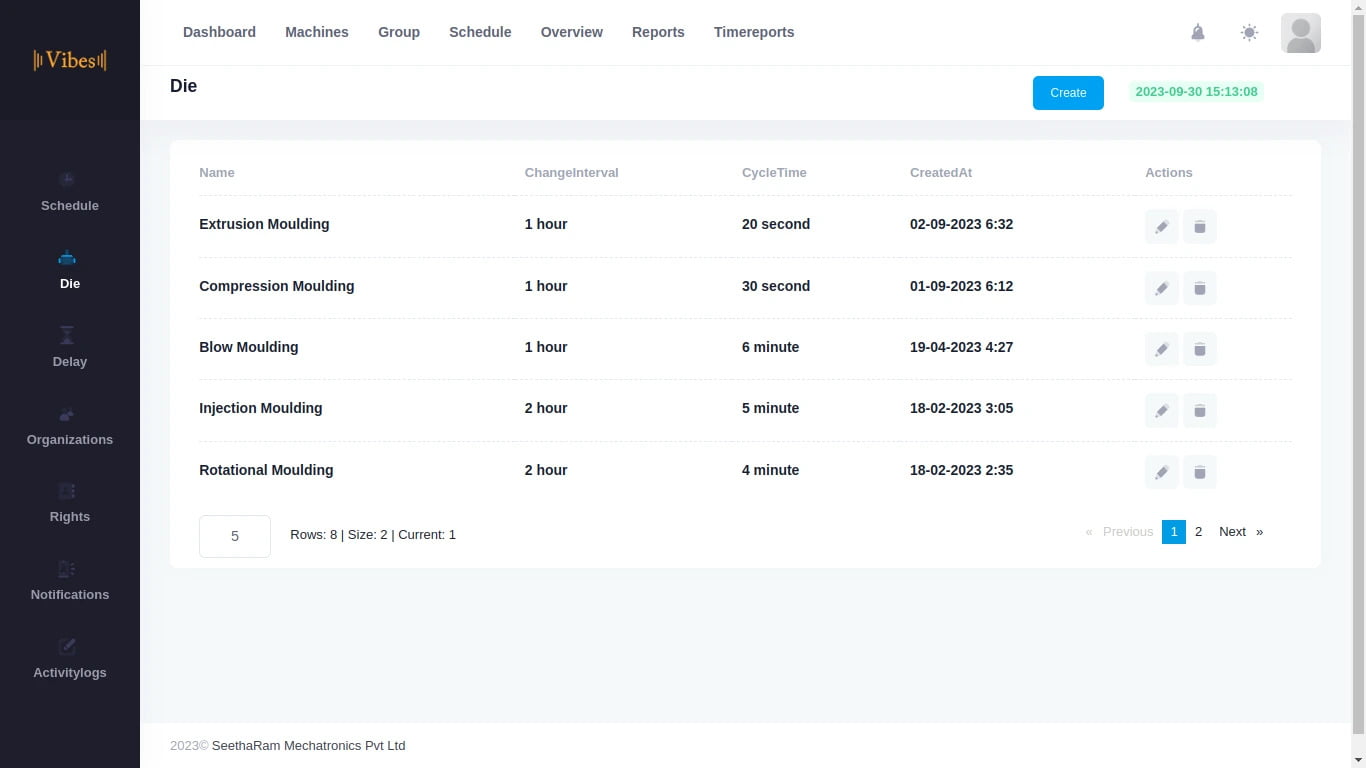

Mould Change

Machine Breakdown

Micro Stops

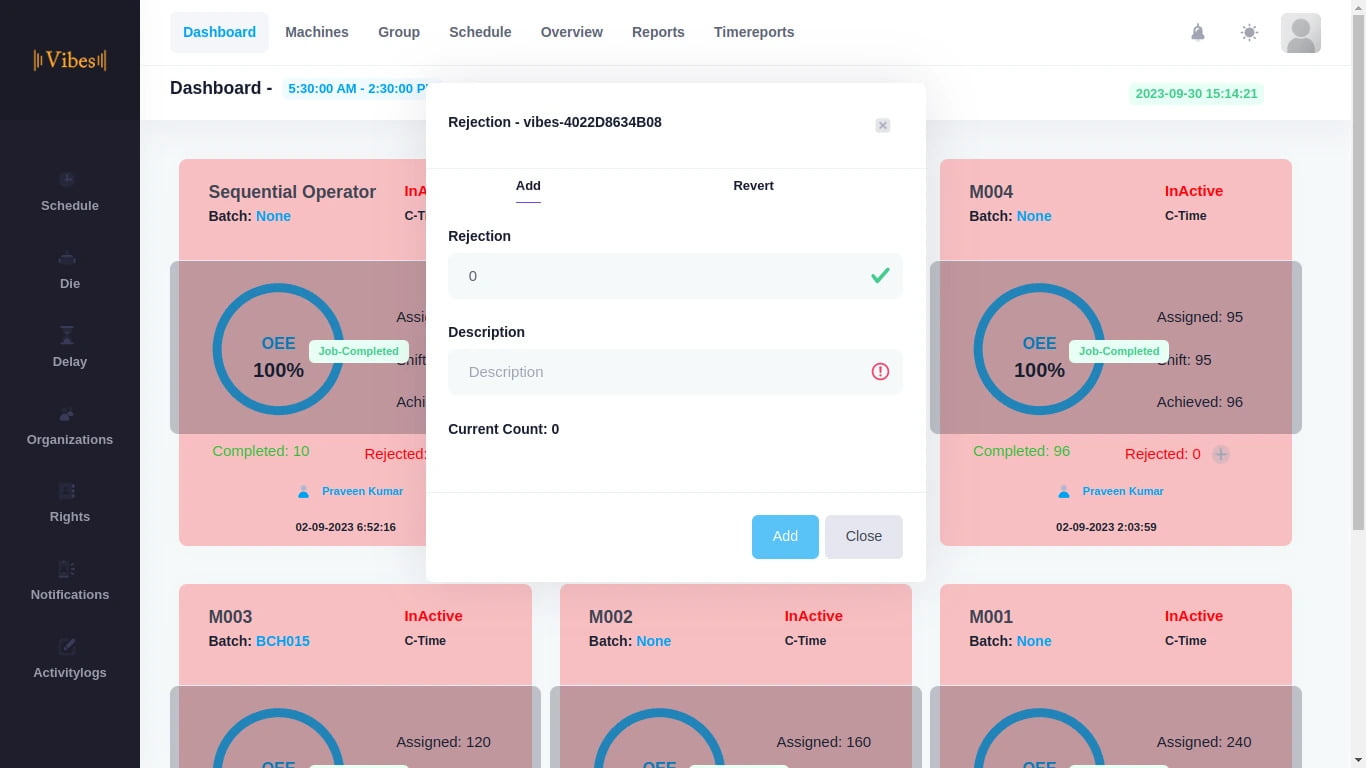

Rejection

Rich & Meaningful Reports

Top Management View

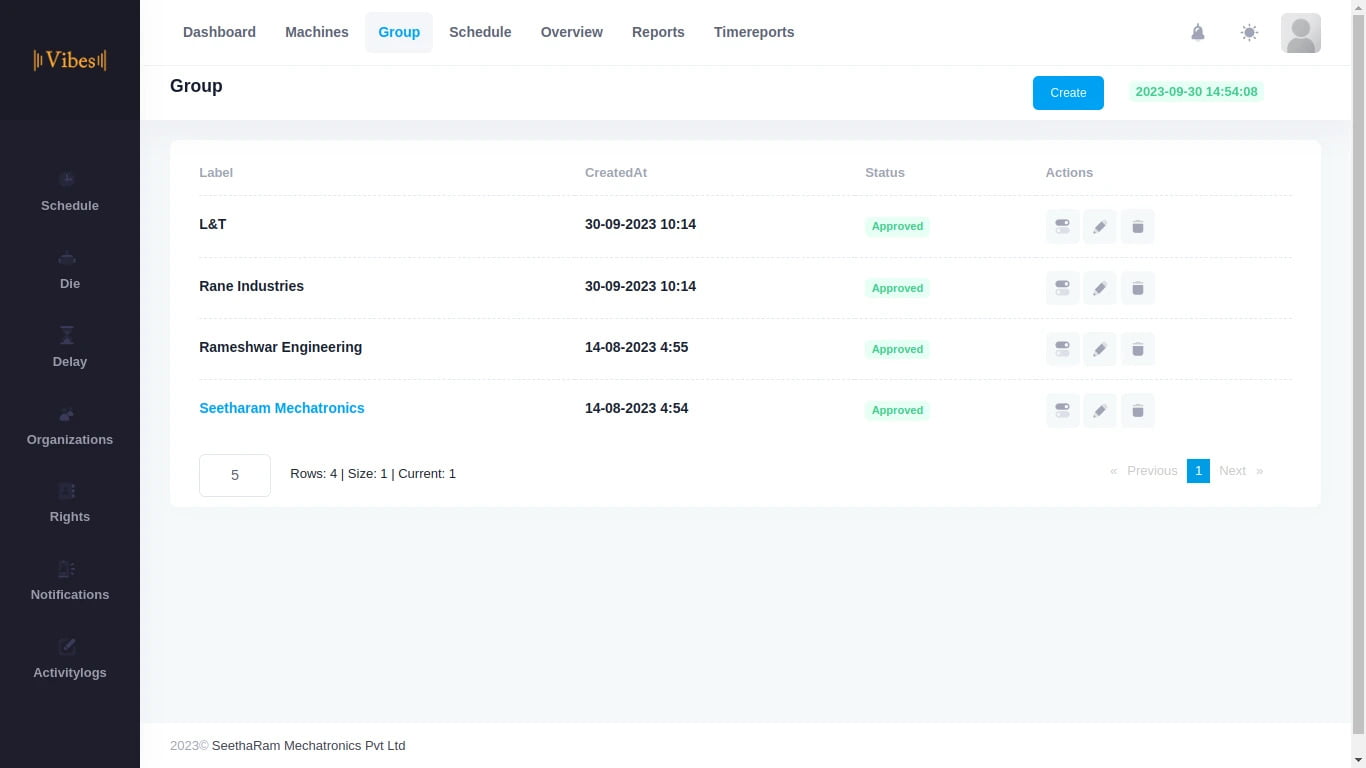

Group Companies

I

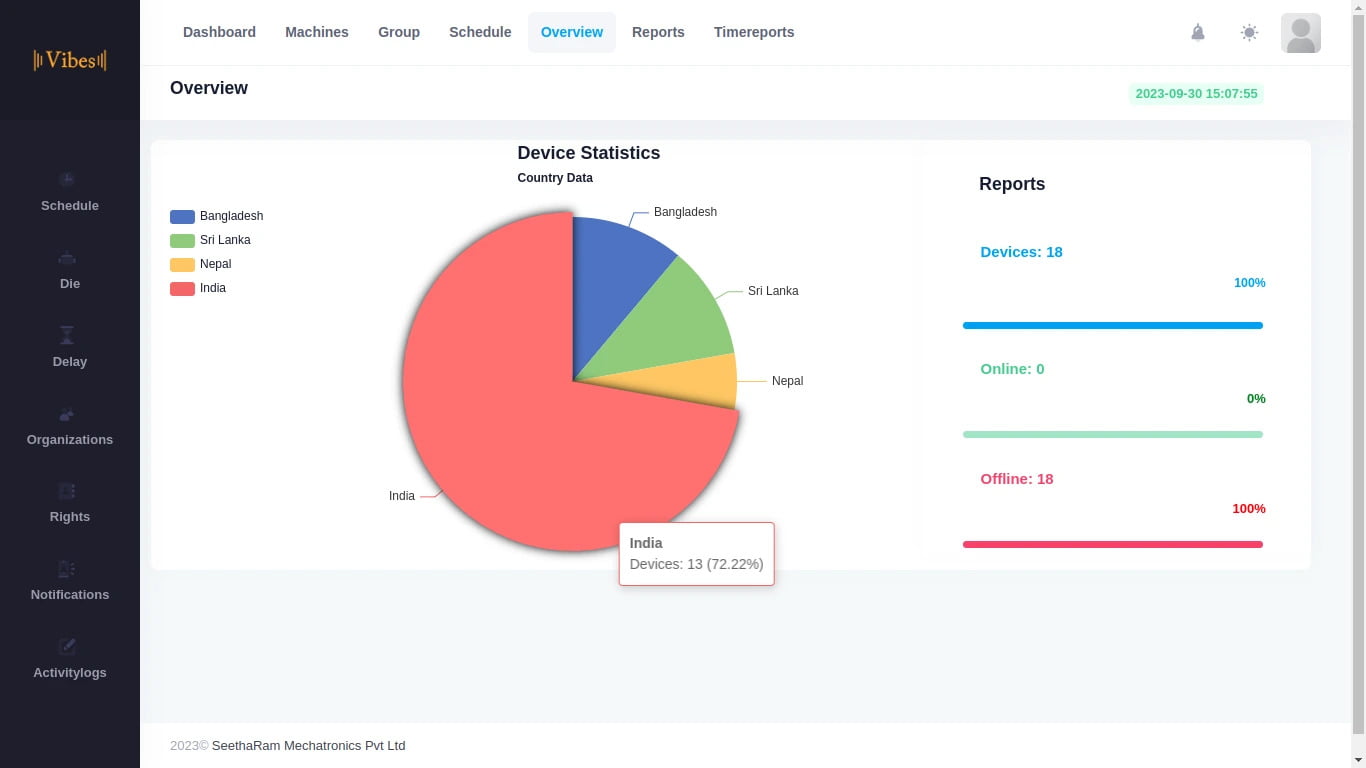

Overview Performance

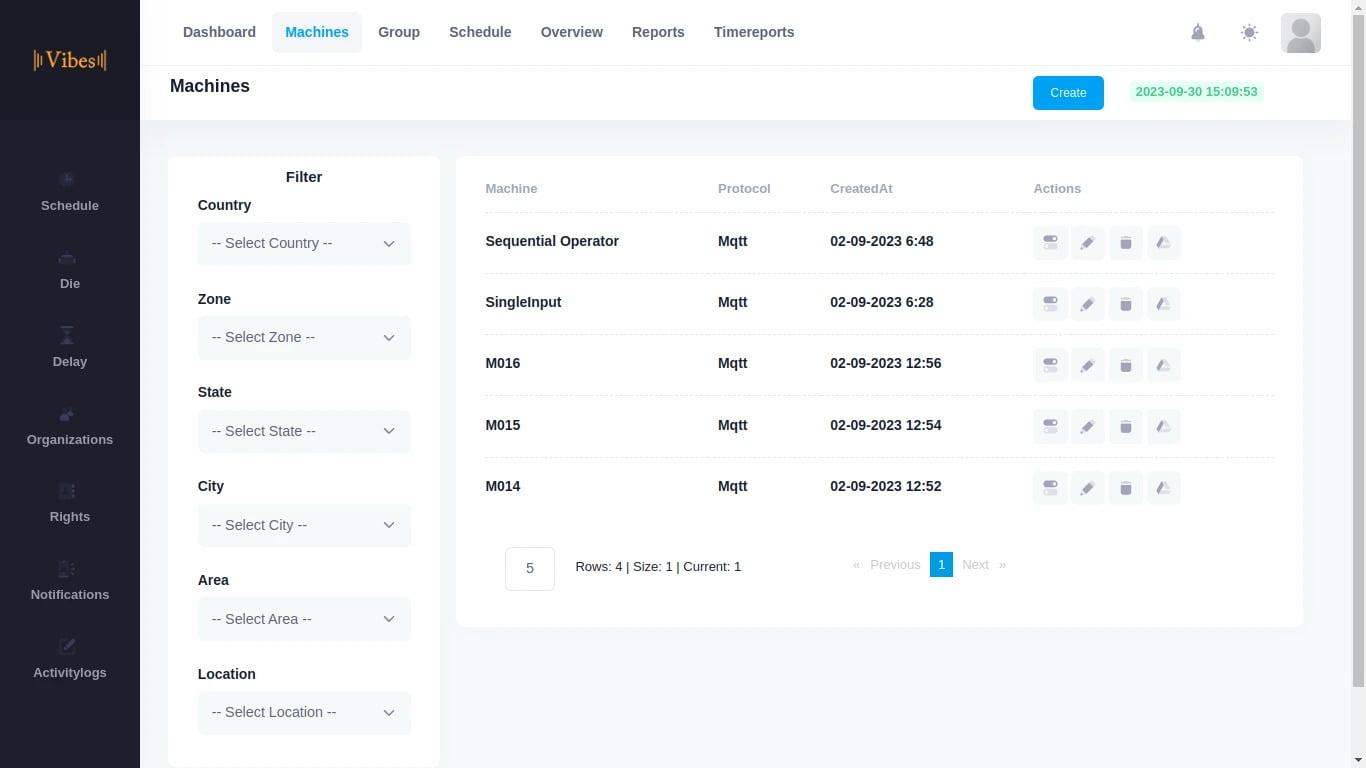

Assets

I

Executive View

Production & Rejections

Mould Master

I

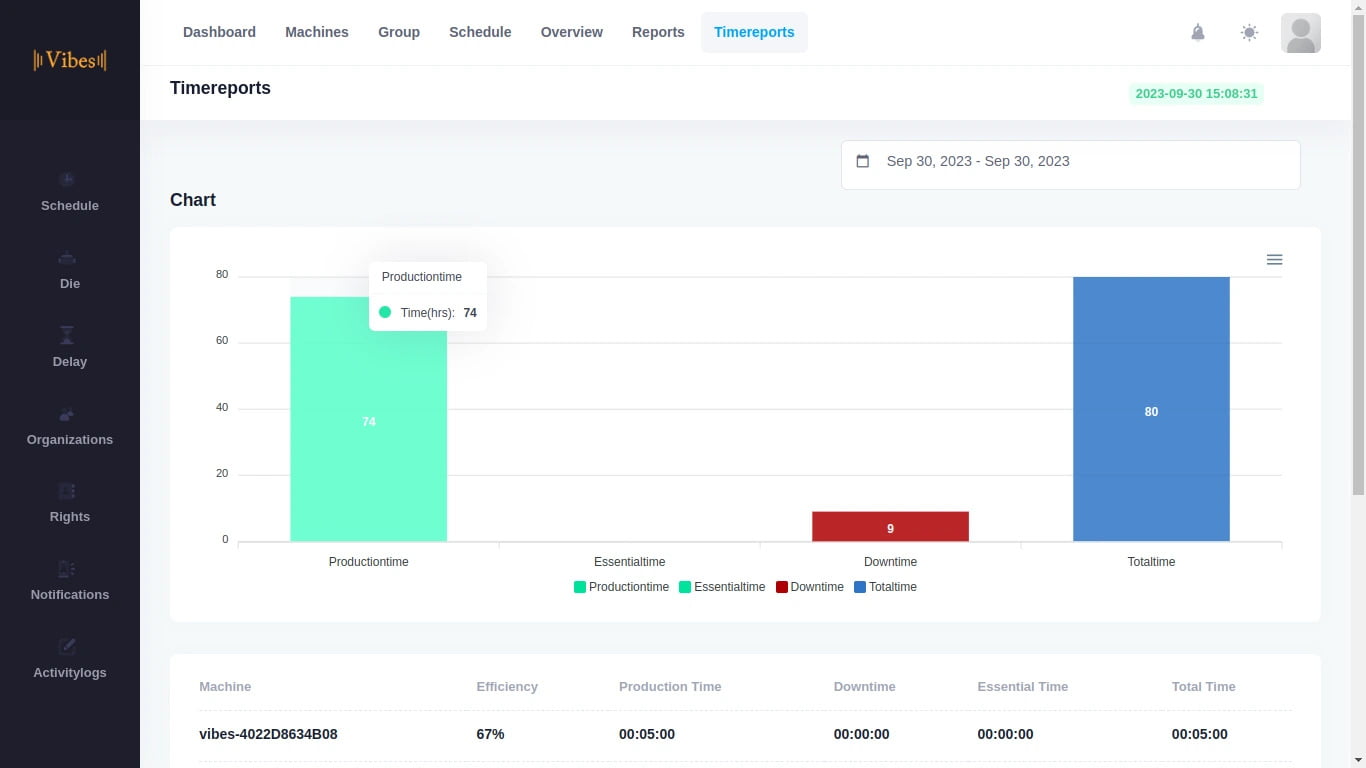

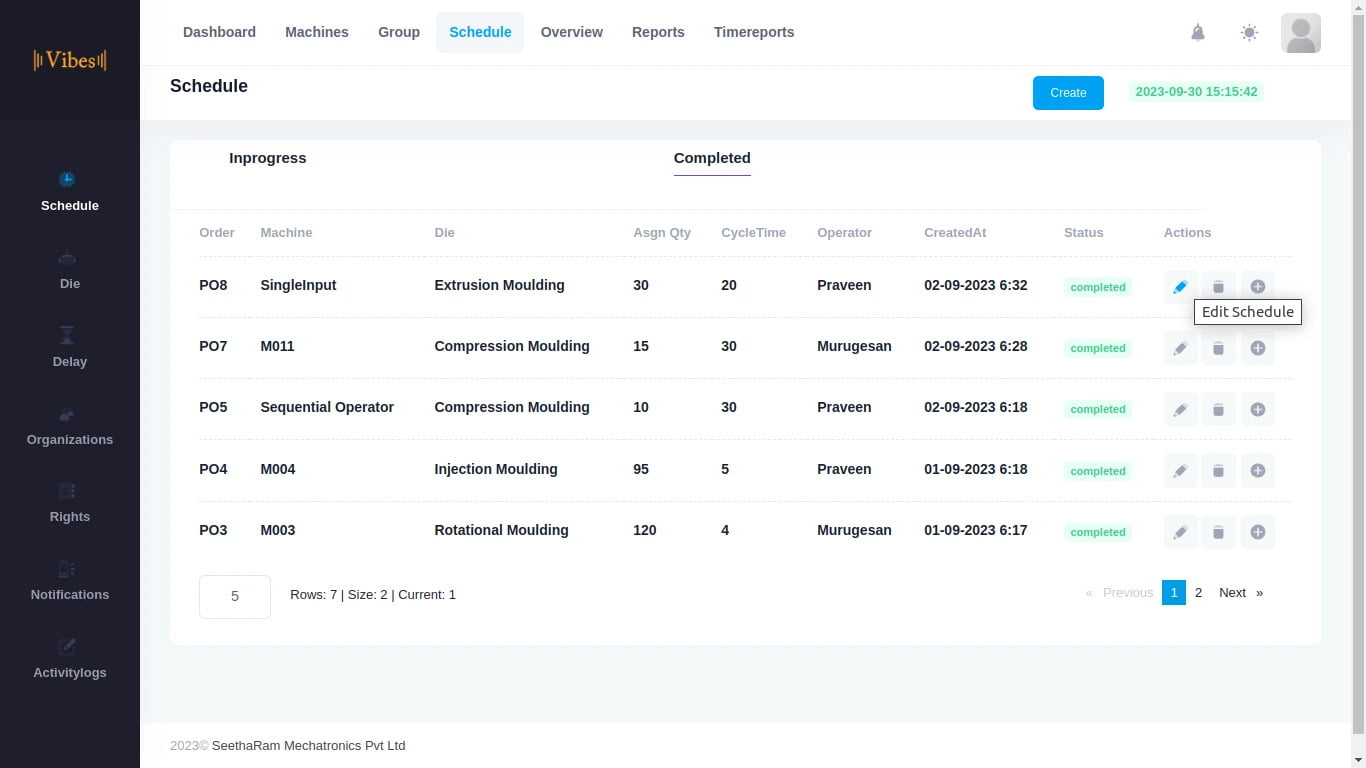

Schedule & Reports

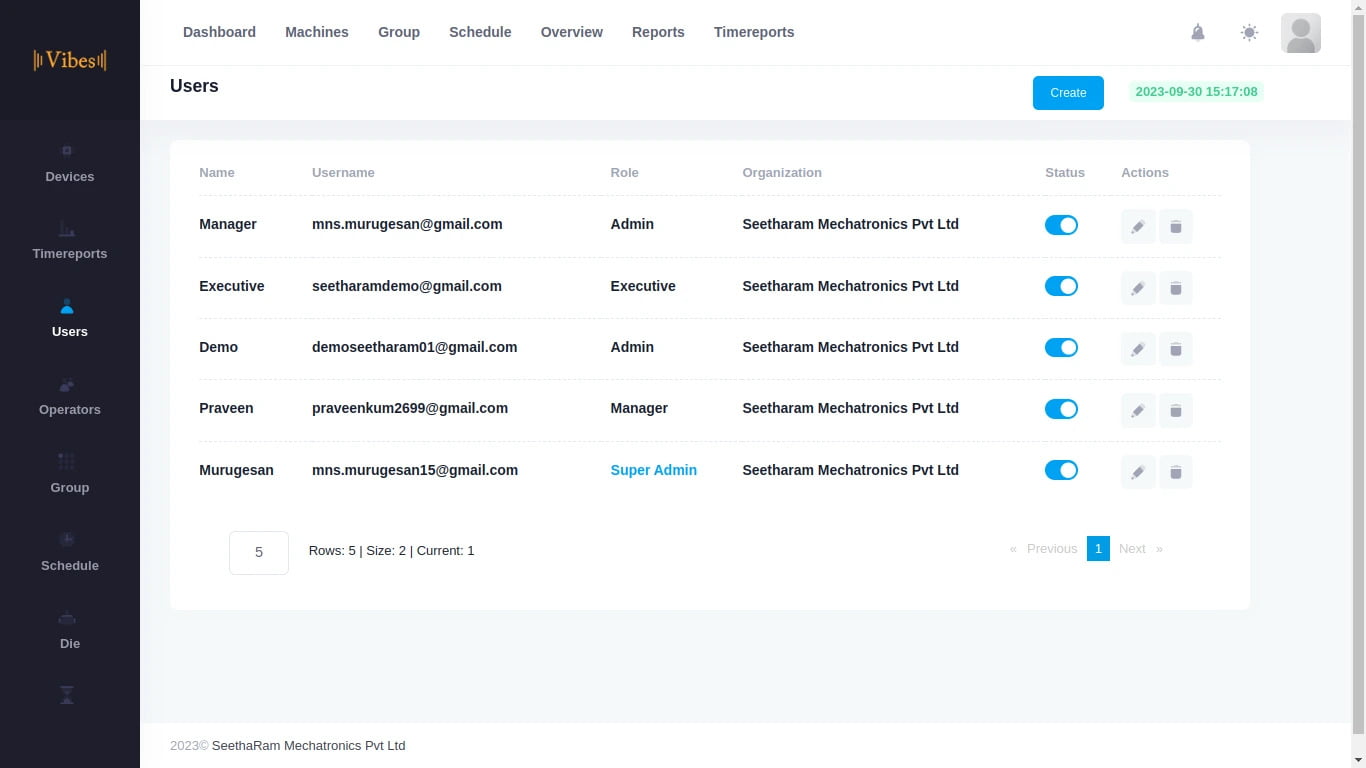

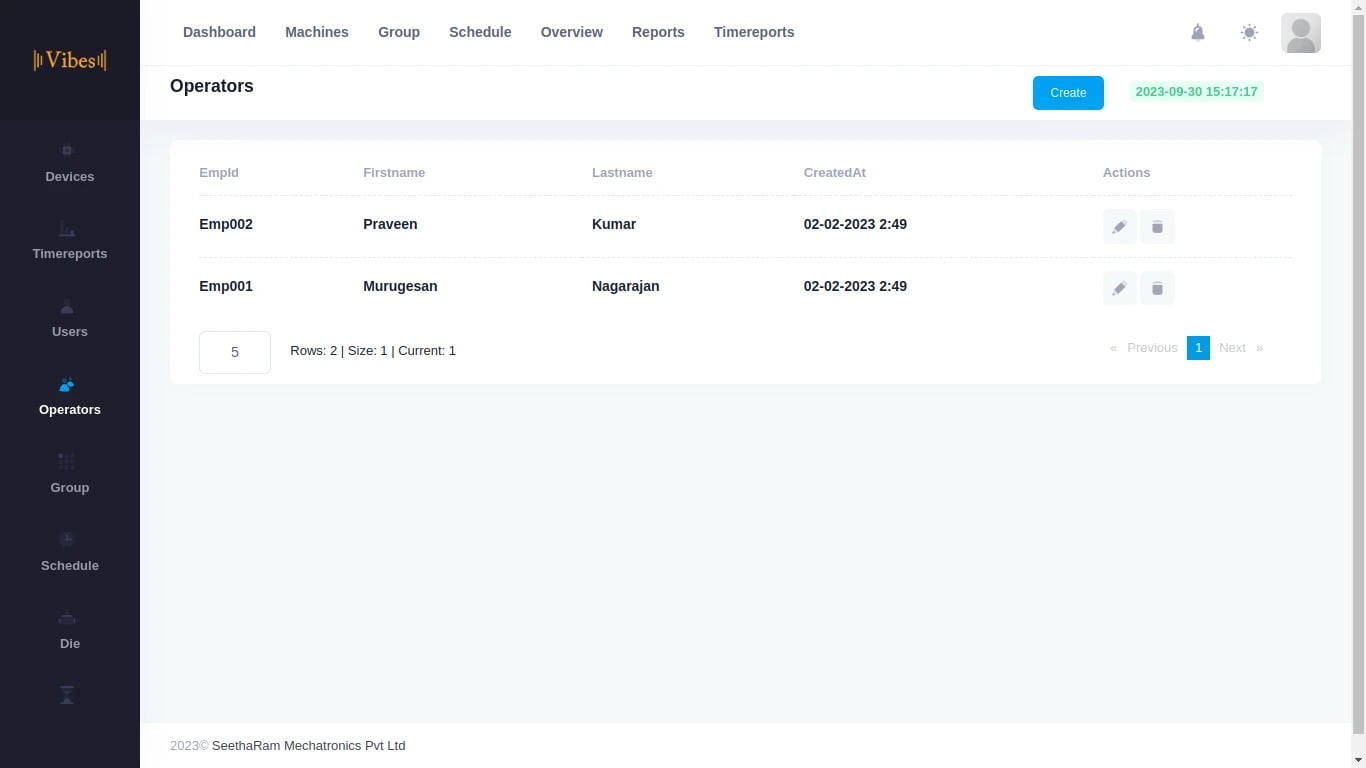

Users & Operators

Inputs & Improve Productivity

Apart from popular manufacturing improvement methodologies such as Lean Manufacturing, Six Sigma, OEE can give you the IDA factors for productivity increase: