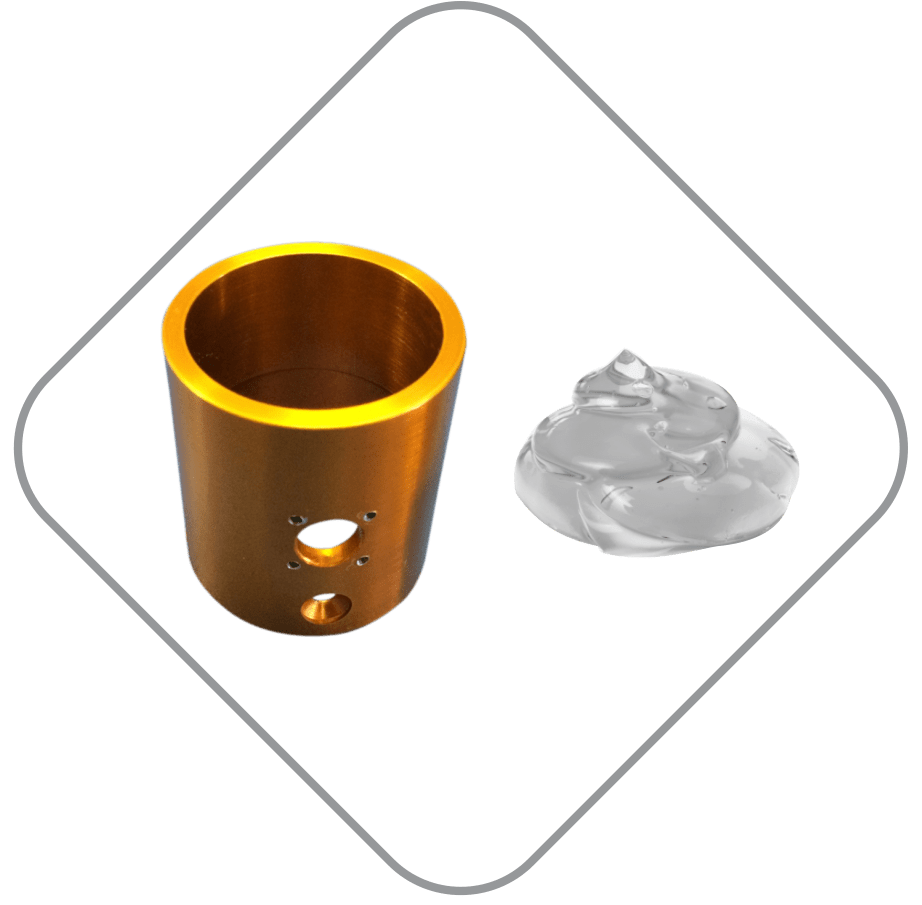

The Industrial load cells also called the Force sensors manufactured by us have distinct advantages and features which give them an edge over competition.

Its simply different. Look at the features and advantages

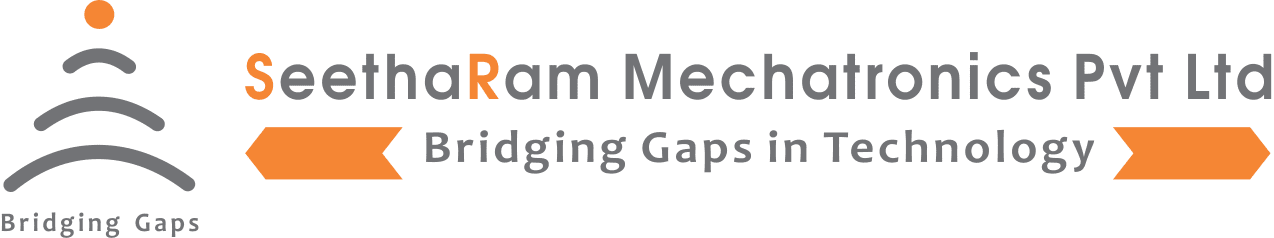

Spring Element

SS17-4PH Stainless Steel Spring Element:

All our force sensors are made from SS17-4PH stainless steel. Why?:

1.Maintains Accuracy with Structural Integrity

“PH” refers to precipitation hardening, which make a metal alloy stronger and stability and reduce

deformation, plasticity, or warping. the uniform corrosion rate for 17-4 PH drops to nearly zero at the 17 percent chromium and low carbon level.

With the best in class structural integrity, the dimensions of the load cell can be considerably reduced and made optimally compact without compromising continued long-time performance.

This is the prime material for force sensors to be used for long life repeatable accurate performance. No wonder, 17-4PH steel is also used in barrel, bolts, for Pistols and Firearms.

Enclosure & Sealants

Less weight Anodized aluminum ensure physical abuse in connector area. Anodizing cannot peel, chip, flake or blister and gives aluminum a deeper, richer metallic appearance.

RTV Silicone Sealants

Room or elevated temperature sealant as fillers for being pressure cushions to ensure “shock-free”, moisture free terminations

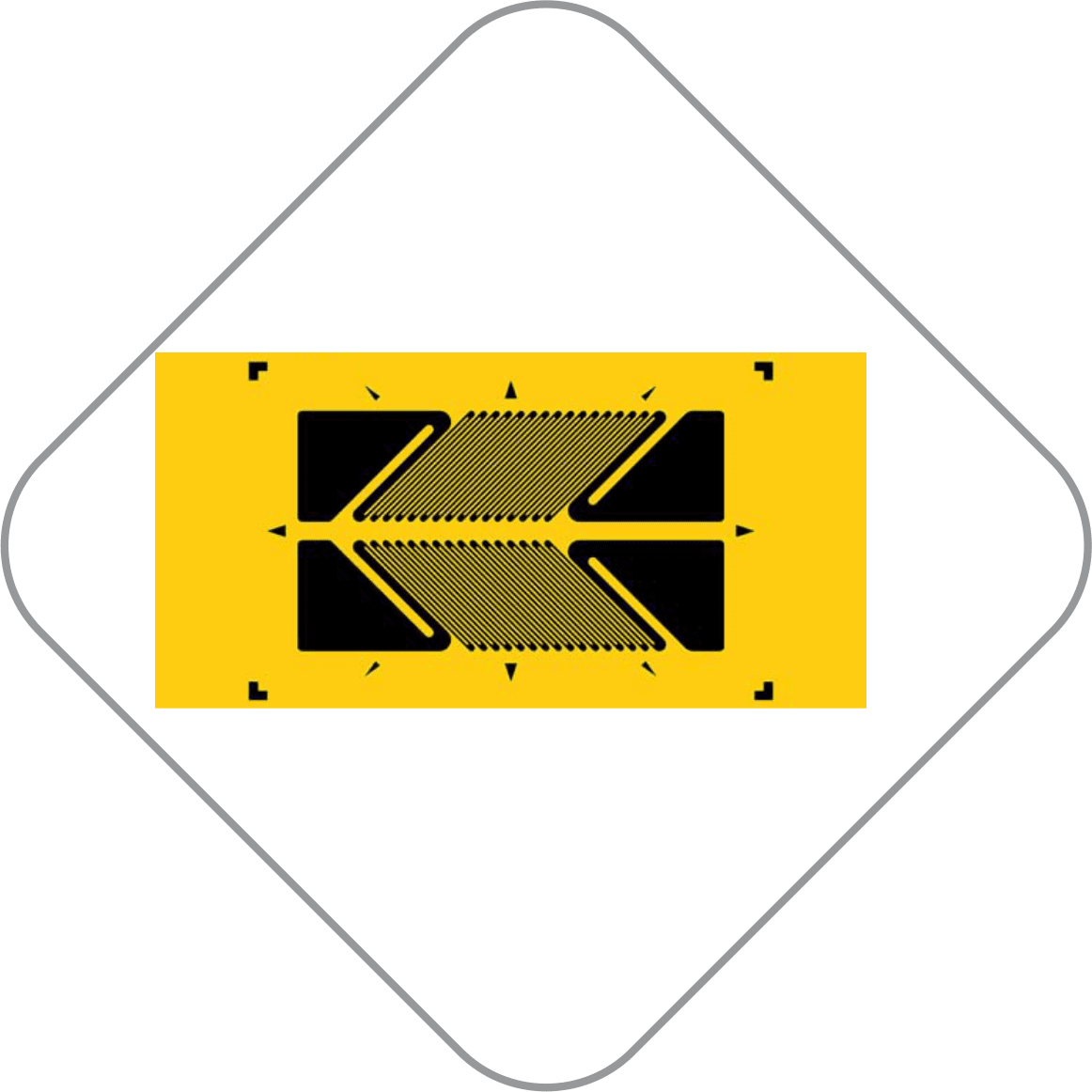

Strain Gauge

Constantan alloy: Highly strain sensitive and effective in even very small grids. Its resistance is constant over a wide range of temperature fluctuation

Polyamide carrier: Ensure tear-proof, crease free, stretchy, Heat & Abrasion-resistant moisture free carrier for strain element.

Cable

Conductor stranding: Stranded, fine-wire, 0.34 mm²: 7-wire.

Minimum bending radius: Occasional flexing: 15 x outer diameter; Fixed installation: 6 x outer diameter.

Minimum Electrical Interference: Optimum Mutual Capacitance & Inductivity and perfect overall Tinned-copper braid minimizes Electrical Interference.

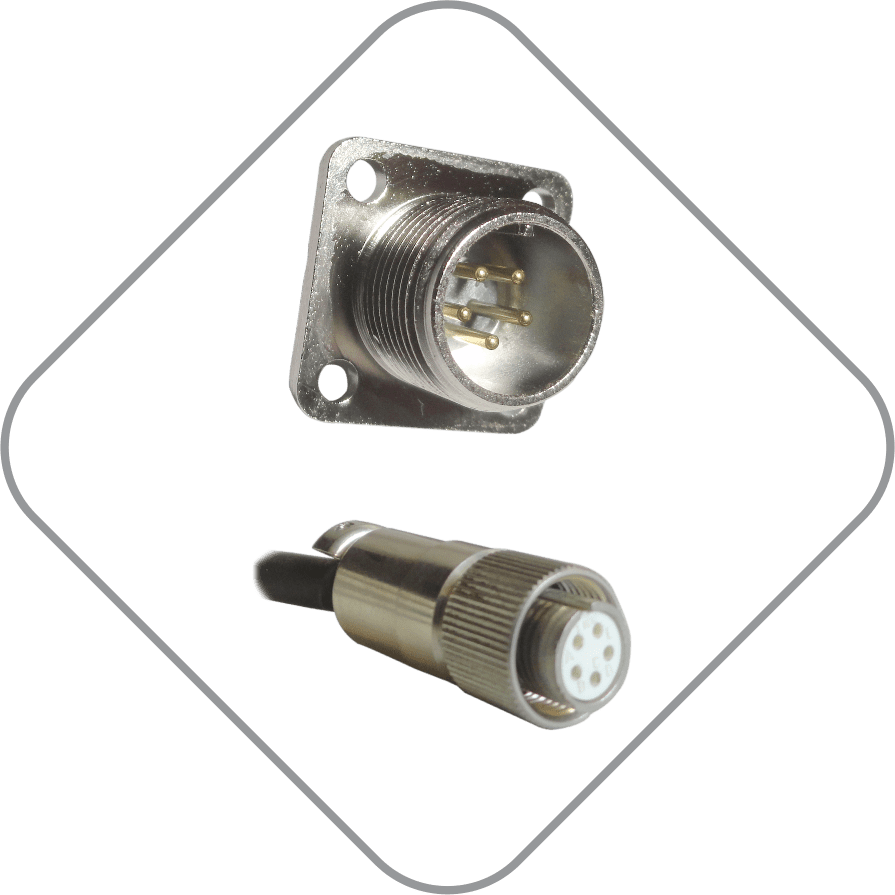

Connectors

Subminiature in size Screw coupling - best suited for compact sized load cells

High Integrity Contact Material: Copper Alloy / Gold over Nickel

Low Contact resistance: As low as 8 milli ohm

High Insulation resistance: As high as 1000Mega ohm for 500V

Corrosion Resistant: Salt Spray corrosion resistant 5% 48H